Rotoweld 3.0

Twin Bay

Get the industry’s highest productivity output

The Rotoweld 3.0 Twin Bay is all about efficiency and arc-on time. Make loading, unloading, grinding and aligning time losses disappear with the twin bay. Prepare your next spool on the second bay while the Rotoweld is completing a job on the first bay. This is how you’ll accomplish up to 300 dia inch in a single 10-hour shift.

3 in. to 42 in.

75 mm to 1,065 mm

Diameter capacity

4,535 kg

10,000 lbs.

Pipe stands capacity

300+ dia inch

Daily productivity capacity

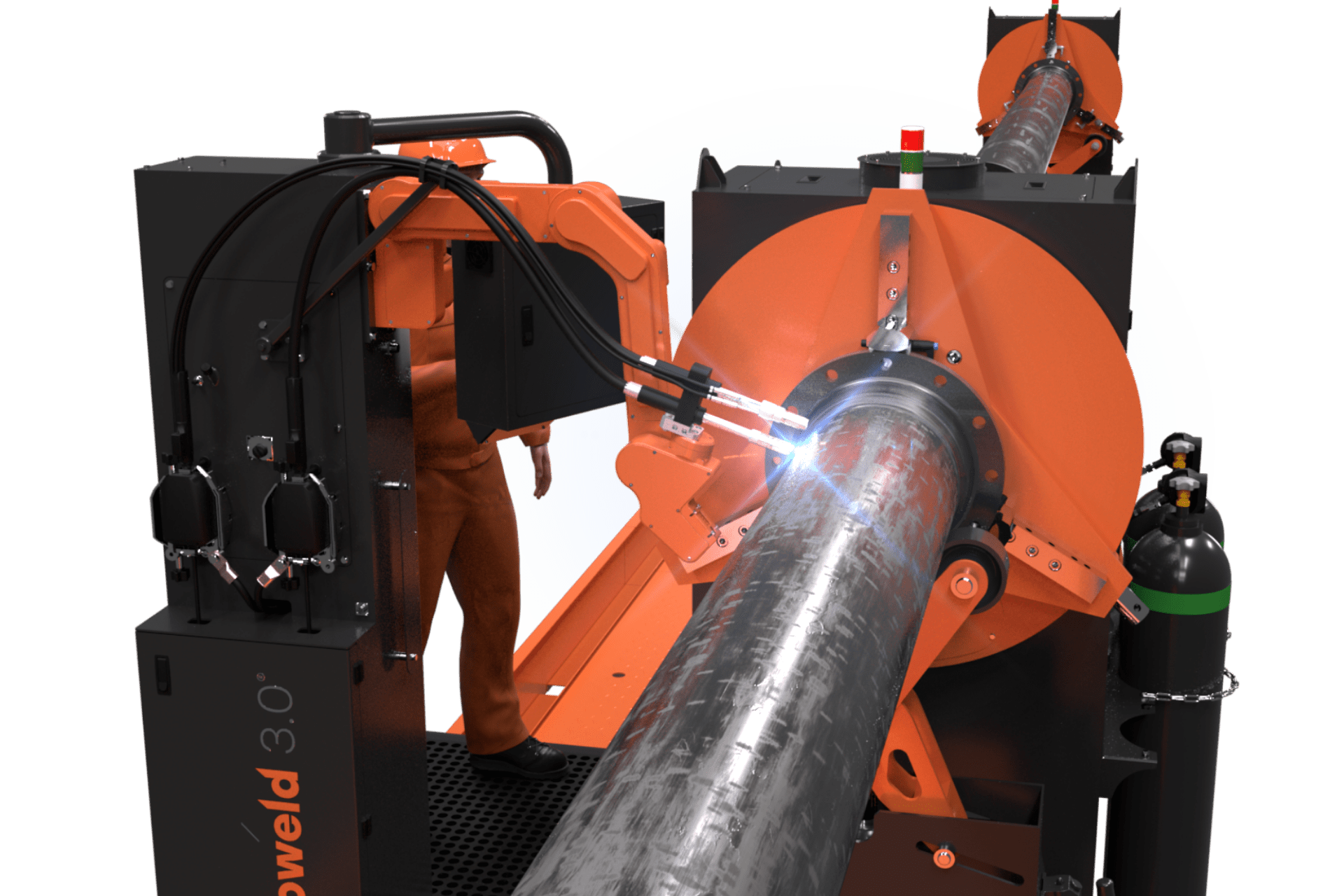

Welding torches and wire feeder

- Designed with 2 welding torches: one to perform open-root-pass butt welds and the other for filling passes

- Each torch has its own wire spools. Root pass is done in GMAW; choices for fill passes: GMAW, FCAW, MCAW.

- Separate gas shielding system for each torch

- Robotized torch welding arm for fast and repeatable torch positioning on selected pipe diameter

- Torches can be easily switched — optional SAW available.

Robotic welding arm

- Self-positioning of the arm in welding position in just a few seconds with no human manipulation

- Welding vision system controls the puddle penetration and adapts welding parameters in real time

- Embedded LED lighting allows the welder to easily align the torch in the bevel before starting to weld

- Optional fillet weld for slip-on flanges.

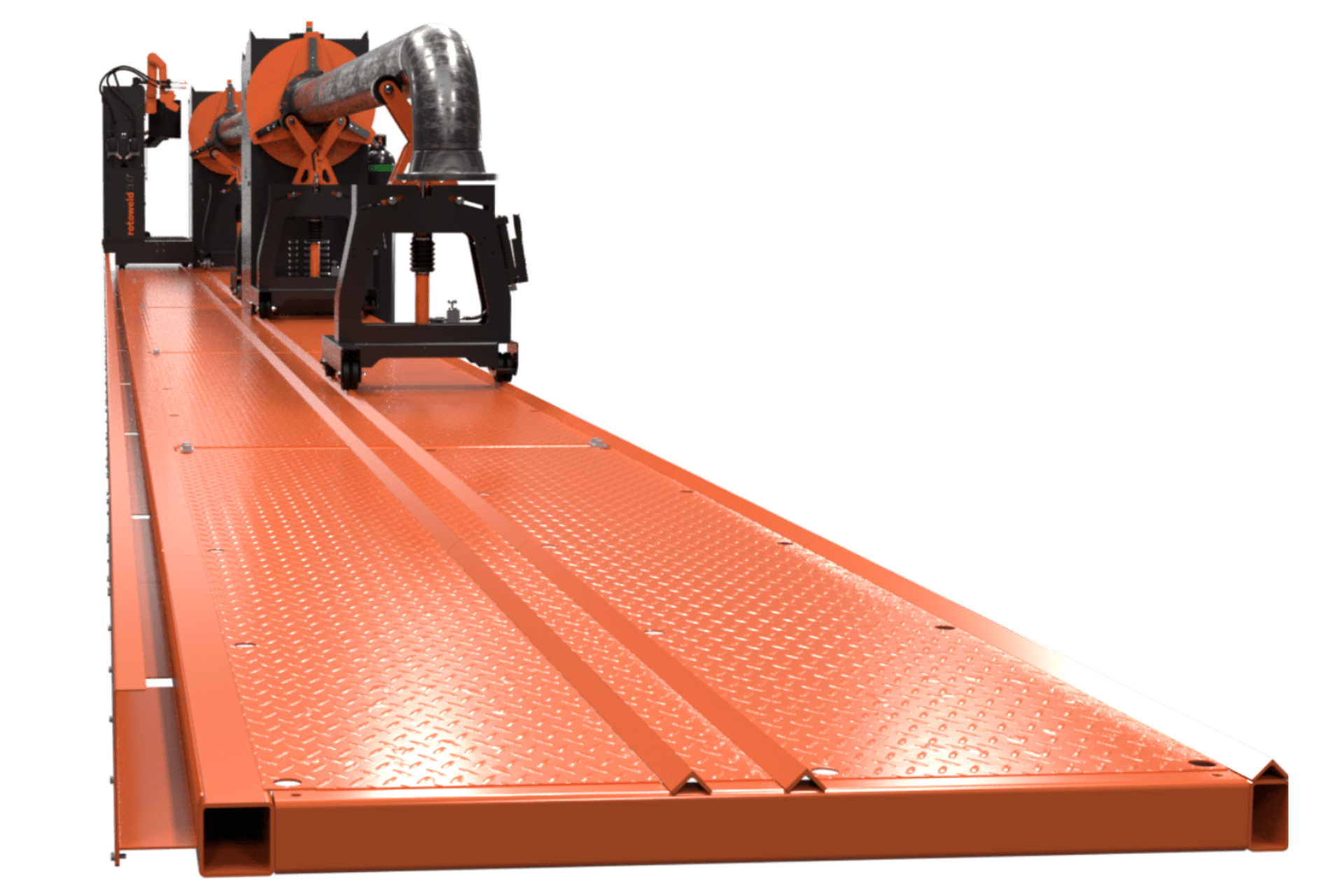

Proprietary designed rail system

- Rails are the backbone of the Rotoweld 3.0 and can be level with any shop floor conditions

- Rails are factory pre-assembled and pre-aligned for maximum on-site precision

- Seamless integration; no wires laying on the ground.

- Welding station and optional fume extractor travel on the rails to desired position simply by using the joystick.

- Twin bay comes with 5 rails for a total length of 80 ft. (24.4 m). You can upgrade a Single Bay Rotoweld to a Twin Bay.

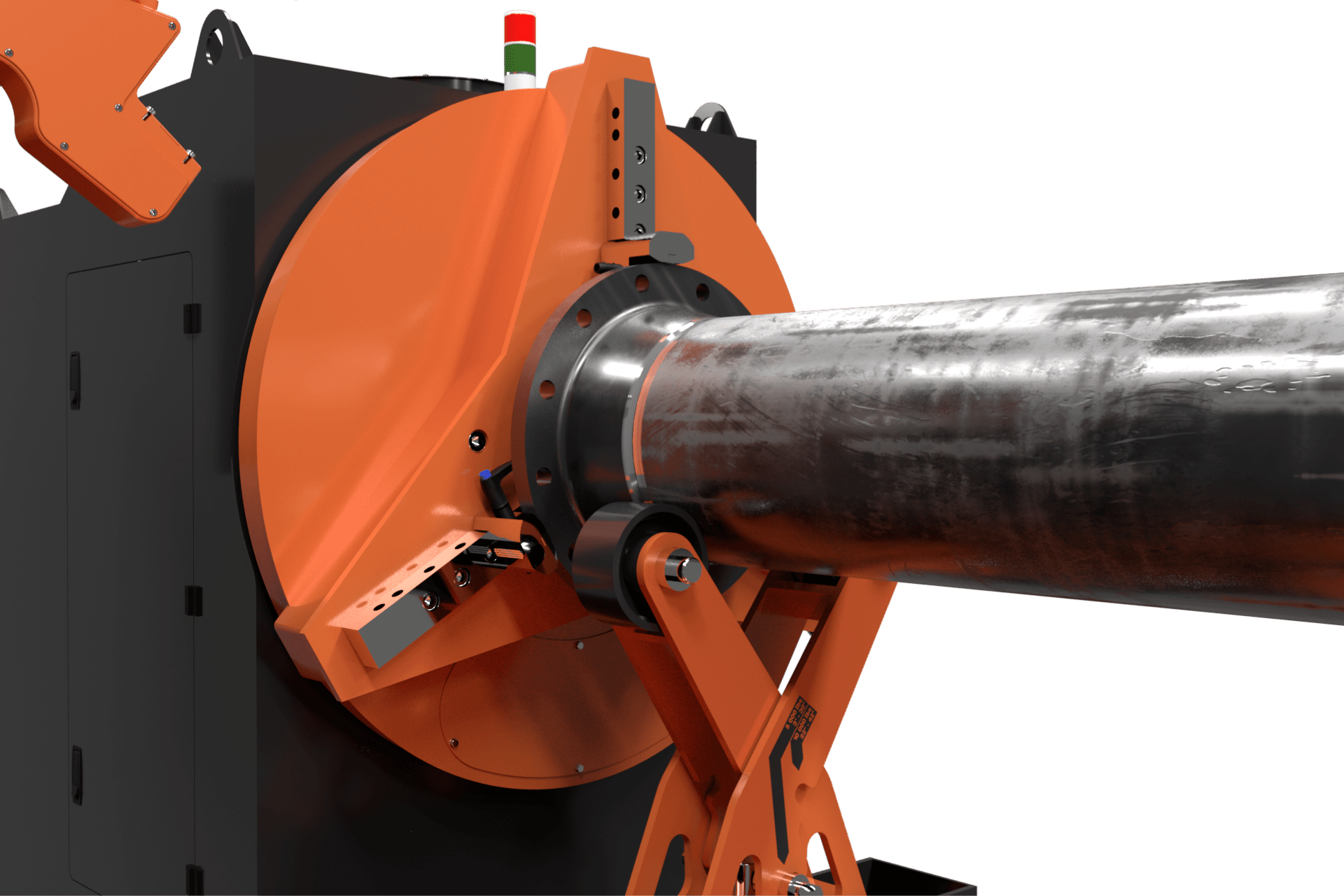

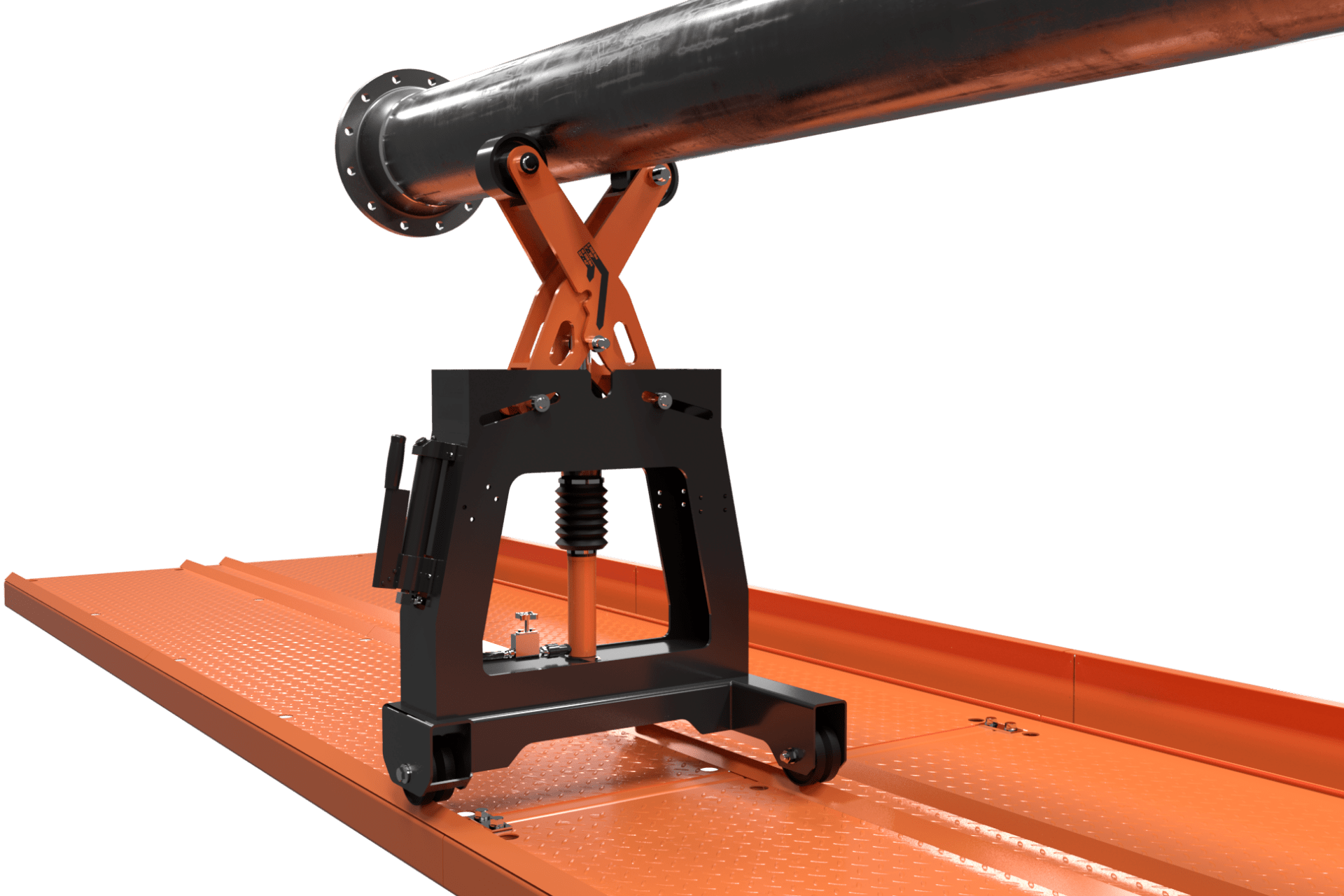

High-torque rotators

- Minimal set-up time required due to its self-aligned design

- Specifically designed for the Rotoweld to have total control of the weld puddle

- Diameter capacity: 3 in. to 42 in. / 75 mm to 1,065 mm

- Centre line clearance to ground: 65 in. /1,605 mm

- Operation speed range: 0.2 to 1.9 rpm

- Load capacity: 3 ,000 lbs. / 1,360 kg

- Maximum torque 50,000 lbs.-in. / 5,649 n-m

- Optional stainless steel grippers.

Heavy-duty pipe stands

- 4 pipe stands that can be moved quickly and easily on the rail while staying aligned with the rotator to guarantee perfect positioning

- A hand pump connected to the hydraulic cylinder levels the pipe section easily, efficiently and safely

- Heavy-duty steel idler rolls allow the pipe to turn freely. Optional rubber idler rolls are available for stainless steel application.

- Diameter range: 3 in. to 42 in. / 75 mm to 1,065 mm

- Load capacity: 10,000 lbs. / 4,535 kg

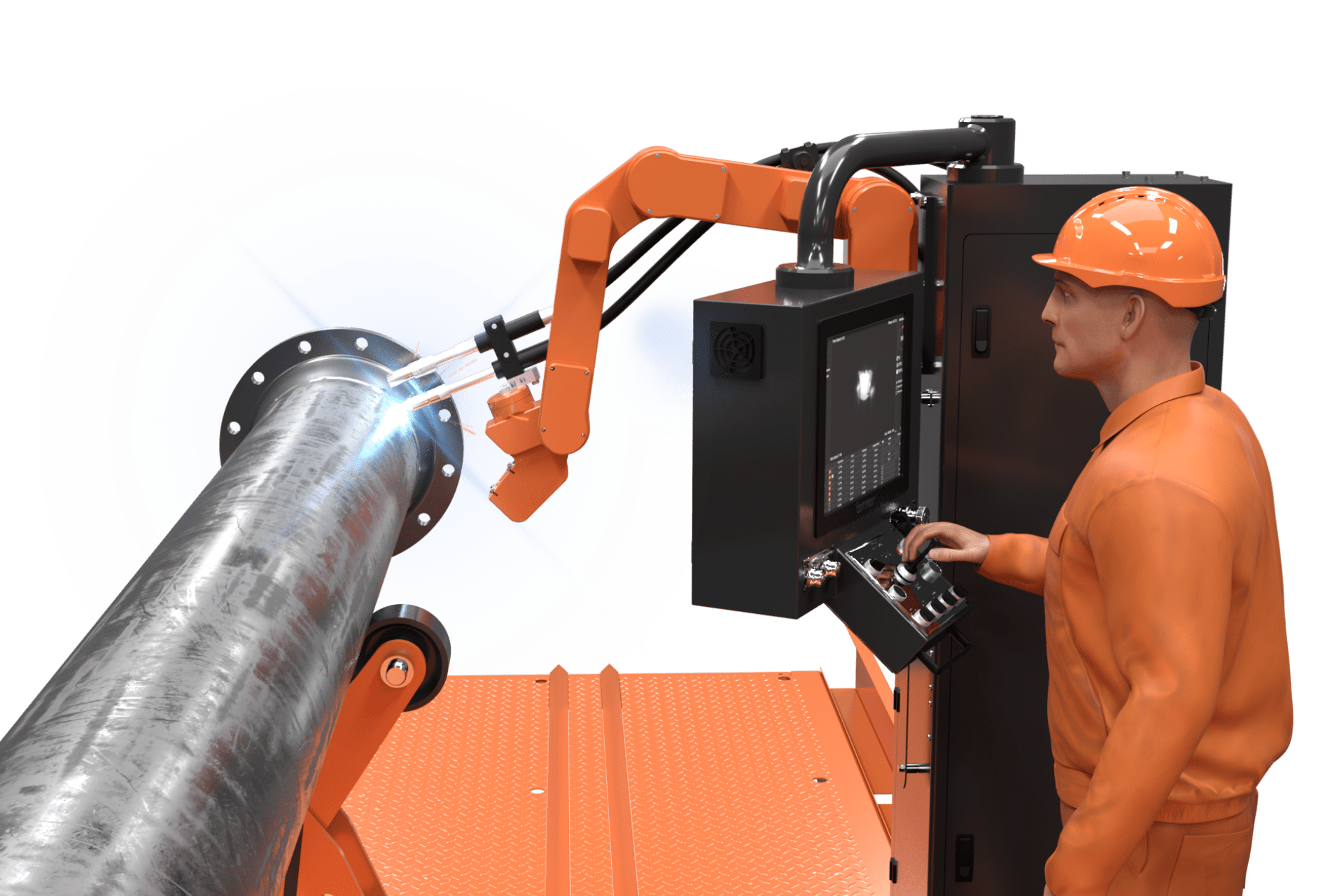

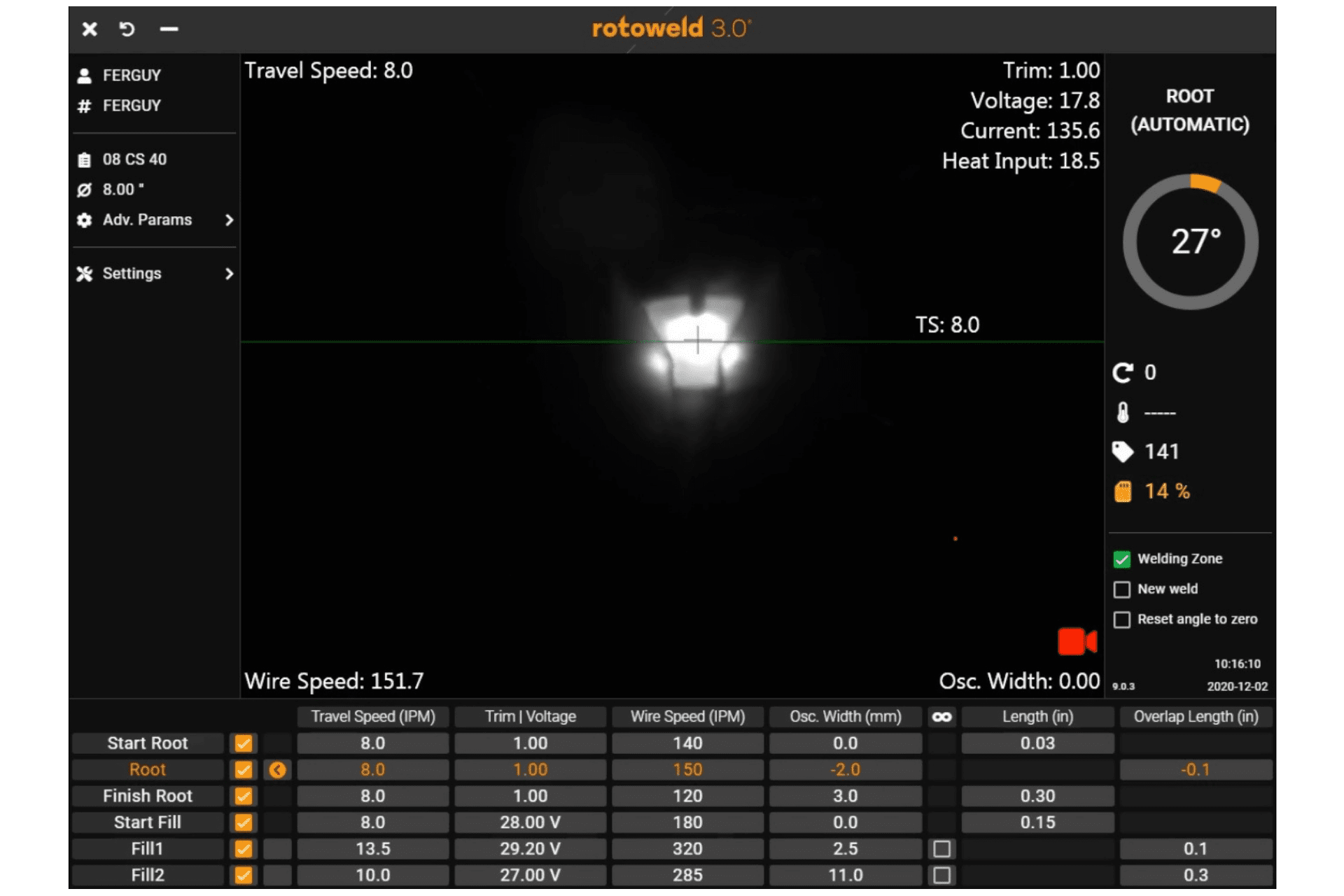

User Interface features:

- UI entirely browsable with the Rotoweld pendant

- Large centred image of the torch in the bevel (arc-off) and the weld puddle (arc-on)

- User and Engineering modes easily toggled with the engineering lock key

- Welding program visible at all times with a live cursor that indicates the progression of the weld

- Expandable menus to enter key information

- Welding information display.

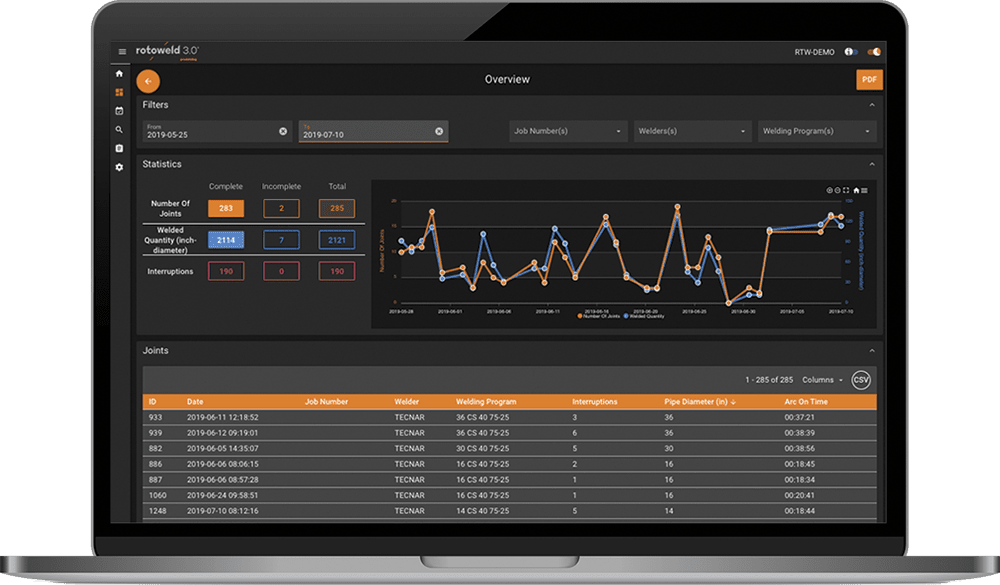

Prodatalog™

Gives you:

- An overview of your productivity for a period of time that can be filtered by welder, welding programs and job number

- A daily report in a chart that contrasts the arc-on time, the complete procedure and interruption

- Details on each joint:

- Displays the welding parameters used for all passes as a function of degree of rotation

- Displays the complete welding program that was loaded for this joint

- Records a live video of each pass, pushing the limits of investigating welding practices or joint preparation

- Displays the temperature measurements and waiting times between passes for temperature-sensitive material.

Available options

Discover how quick and easy it is to get your Rotoweld

1. Get a quote

Let our specialist find the right model to suit your production flow and specific needs. In less than a week you’ll have all the information you need to make your purchase decision.

2. Fabrication

The Tecnar factory releases a new Rotoweld every 3 weeks. Based on demand, the average delivery time is between 3 and 9 weeks. Be sure to get in line.

3. Installation and training

A Rotoweld specialist will complete the installation in 2 days and train your entire team for 3 days to ensure your Rotoweld performs at its best.

Technical specifications - Rotoweld 3.0 Twin Bay

Materials

Carbon steel (including A333 Gr. 6)

Stainless steel (304,316 and similar)

Cr-Mo steel alloys

Duplex stainless steel

Welding processes

Root pass

GMAW (short circuit)

Fill pass

GMAW (spray or pulsed transfer)

Fill pass option

SAW (submerged arc)

FCAW (flux core)

Rotator

Diameter capacity

75 mm to 1,065 mm

3 in. to 42 in.

Center line clearance to ground

1,605 mm

65 in.

Operation speed range

0.2 to 1.9 rpm

Load capacity

1,360 kg

3,000 lbs.

Maximum torque

5,649 n-m

50,000 lbs.-in.

Pipe stands load capacity

4,535 kg

10,000 lbs.

Dimensions

Width

2.3 m

7.5 ft.

Height

2.8 m

9.2 ft.

Length

19.5 m or 24.4 m

64 ft. or 80 ft.

Welding source

Root pass - STT

Lincoln Power Wave® S500

Fill Pass - GMAW

Lincoln Power Wave® S500

Fill Pass - SAW (option)

Lincoln Flextec 650

Interested in getting into pipe spool welding automation?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.