Rotoweld 3.0

The ultimate automatic pipe spool welding robot

A fully proven and recognized technology with over 35 years of performance reliability in automated welding and hundreds of commissioned Rotowelds around the world.

Talk to an expertGet the Rotoweld 3.0 advantage

The Rotoweld 3.0 is the ultimate automated welding solution to increase your productivity and stay competitive in today’s fabrication industry.

Experienced pipe welders are hard to find and fabricators want to increase their productivity while delivering high-quality products and reducing production delays and costs. That’s why access to the latest information on your production floor is crucial to making sound decisions.

Minimal welding experience required

The Rotoweld 3.0-iQ features the advanced automatic welding technology, of PerfectPass-iQ™ to automatically adjust welding settings in real-time, adapting to changes in fitting preparation and overall conditions. With just a press of the start button, operators can efficiently perform ASME Section 9 welds.

400% productivity increase in your pipe fabrication shop

The Rotoweld 3.0 is dedicated to optimizing arc-on-time, enhancing ease of use and automating the welding process. Each piece of equipment is designed to minimize handling impact. With its upgraded operating system, PerfectPass-iQ technology, the Rotoweld 3.0 executes root-pass, fill pass and cap in record time, adapting to various joint-preparation conditions.

As a rule of thumb, typical Rotoweld 3.0 welding times are as follows:

- 1 min./dia inch for standard wall pipes

- 1.5 min./dia inch for heavy wall pipes

Learn more about the equipment

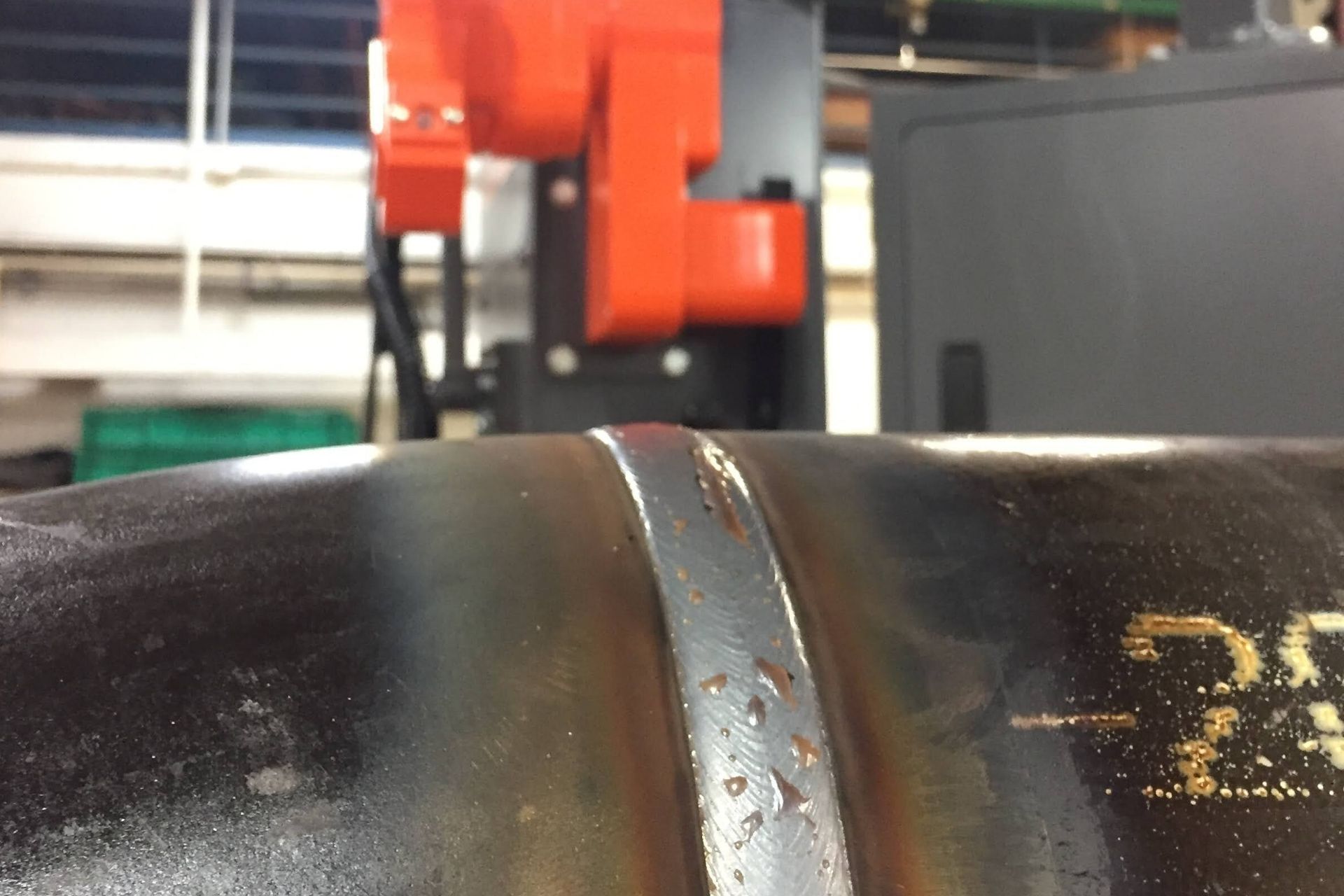

High-quality weld — every single time

Making consistent high-quality welds has never been easier with the Rotoweld’s factory-aligned, rails-based design, robotized torch positioner, proprietary welding intelligence software and advanced built-in welding programs.

Remote tracking of every arc weld you make

The Prodatalog™, a monitoring software developed especially for the needs of fabricators and welders, helps manage and track the performance of your Rotoweld 3.0.

The easy-to-use web-based interface accurately logs and records all joints so you can quickly identify any quality issues and create reports.

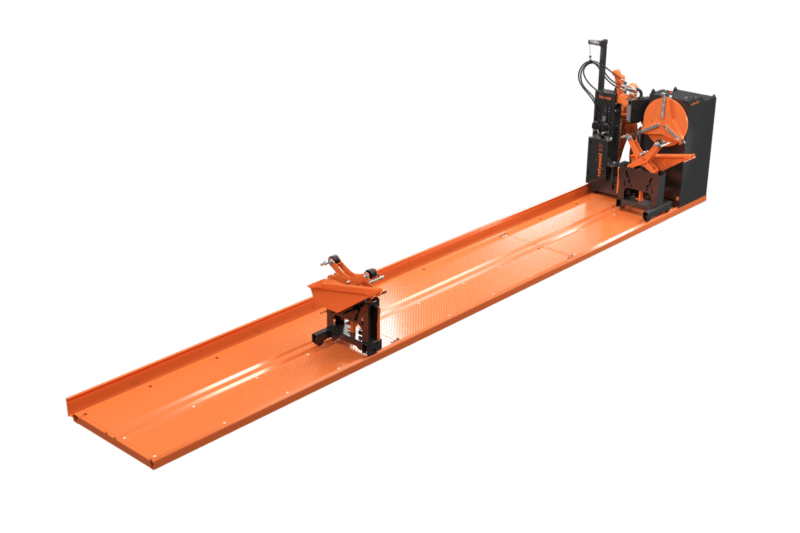

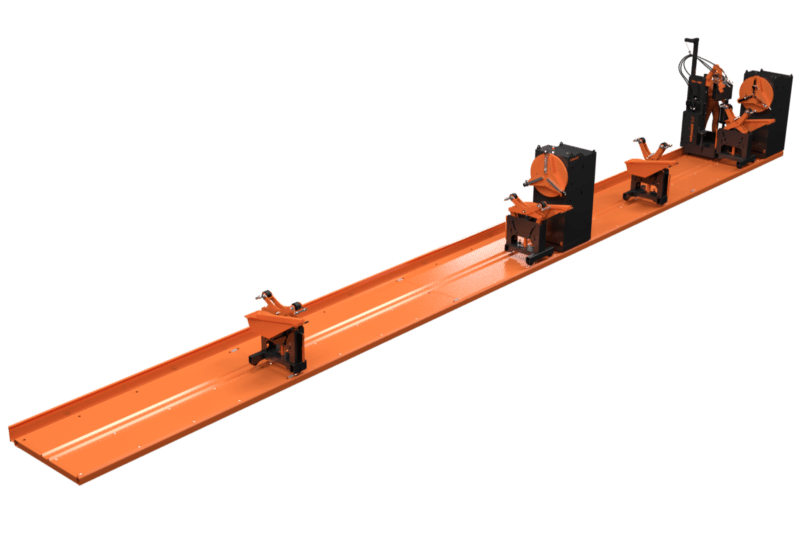

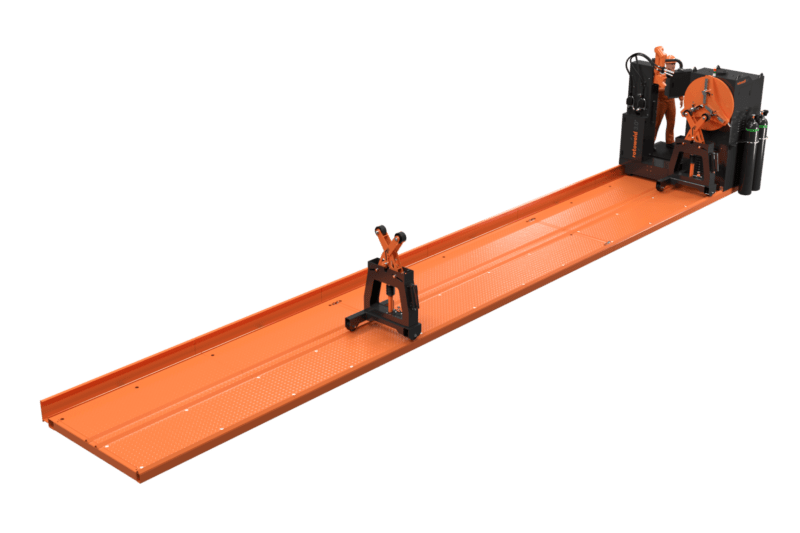

Customizable to your reality

The Rotoweld 3.0 is available in many configurations. Choose between single, twin bay or heavy-duty models according to your shop production needs. Add an optional integrated fume extractor to reduce fume exposure and manipulation for welders.

Available in the process you need

- GMAW

- SAW

- FCAW / MCAW

Improve welder’s working conditions

UV protection: Rotoweld operators don’t need to get close to the arc, leaving them free from UV exposure, which is an important cause of skin injury and a long-term concern for welders.

One-touch welding control: requires minimal intervention and movement from the welder, contributing to sustainable operations.

Camera-based: prevents welder fatigue and increases productivity.

Ergonomic welder position: minimizes fatigue and prevents injuries.

Self-aligned fume extraction: ensures better vent positioning without any manipulation on the shop floor.

Meet our pipe welding robot

The Rotoweld 3.0 is the result of 35 years of experience and evolution. It sets new standards for quality and consistency to compete in today’s market, offering the ultimate solution to the labour shortage.

About Tecnar

Tecnar is a family-owned company that was founded in 1989 as a spin-off from Canada’s National Research Council. Tecnar has 35 years of experience in automated pressure pipe welding and hundreds of commissioned Rotowelds around the world.

Nowadays, Tecnar has expanded to four distinct product lines that share a common goal: to make a difference in the daily life of its clients by integrating its technology and know-how.

Ongoing support and warranty

Tecnar takes pride in offering the best manufacturing/engineering warranty and support in the business so you can rely on Rotoweld 3.0 technology for years to come.

But don’t just take our word for it… take it from our customers.

Interested in getting into pipe spool welding automation?

Leave your details so our experts can contact you. Our team will answer all your questions and suggest the best solution for your needs.