Rotoweld produced X-ray quality welding within five days of installation at Johnson Controls Inc.

JCI is a leading global manufacturer of equipment for API- (American Petroleum Institute) focused applications, such as oil, natural gas, and petrochemicals.

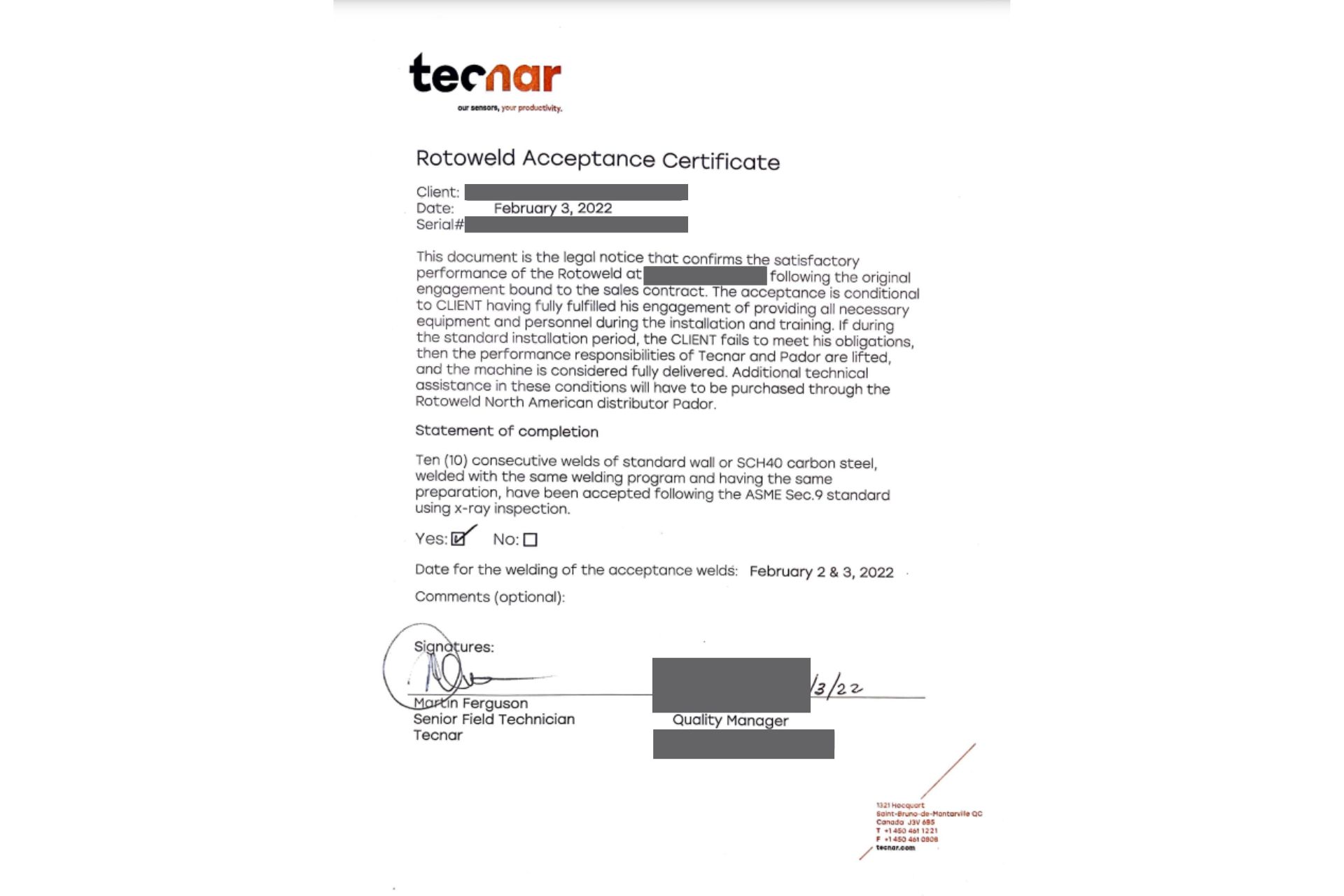

Strict factory acceptance test was passed in five days after opening the crates

Johnson Controls was founded in 1885 and since then it has focused on efficiency and resource conservation. Constantly exploring ways to improve welding safety, quality, and productivity; JCI made the decision to purchase a Rotoweld in 2021. Quality is critical to JCI, so 10 sample spools were welded by JCI’s operators during their three day training on Rotoweld and subjected to X-ray testing as per ASME Section IX Standards. All 10 X-rays passed the test and production with the Rotoweld started immediately. Ever since, JCI has experienced improved productivity, while achieving higher weld quality.

cycle time

welding defects

operator safety

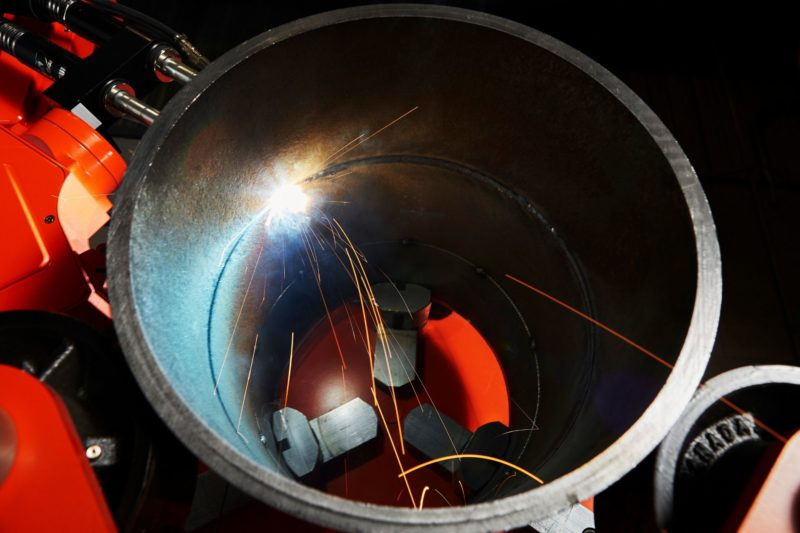

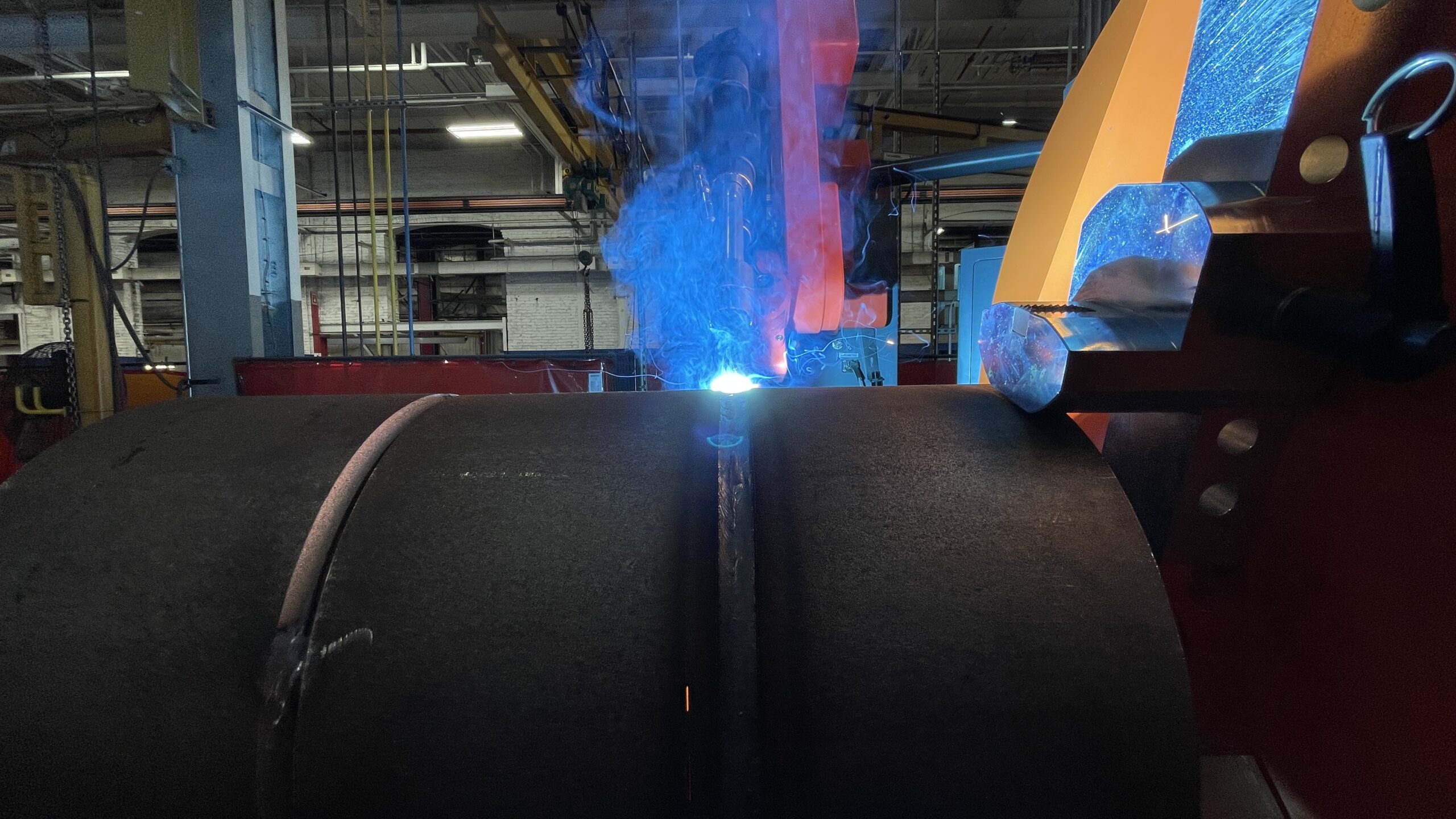

JCI has increased workplace safety by automating pipe spool welding

Moving the welder away from the heat and fumes of arc welding improves working conditions. Operators no longer need welding helmets because they view welding with the integrated video camera.

Ask for a demo today

We have over 150 Rotowelds at work around the world today. If you want to see a Rotoweld 3.0 in action we can certainly make it happen.