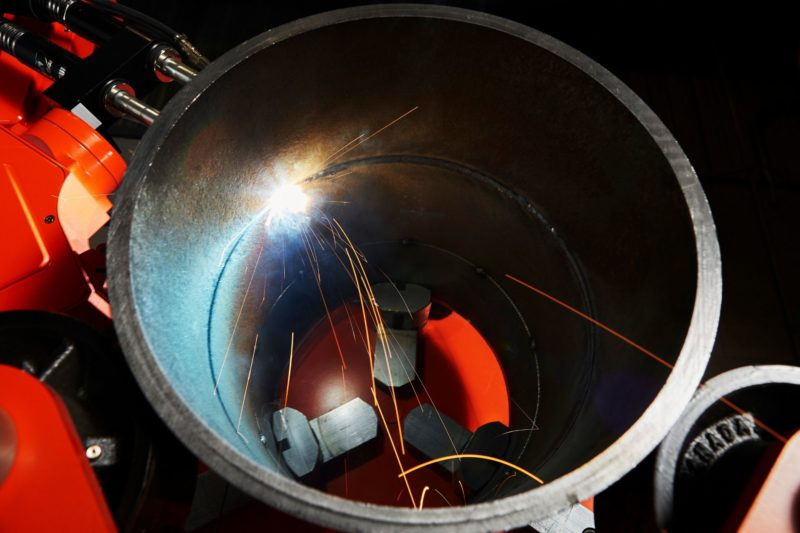

Productivity and quality of pipe spool welding are increased by welding automatically with Rotoweld

Thermacor Process is a leading provider of pre-insulated piping systems in the industrial, commercial, institutional, power generation, and military piping markets, among others.

Consistent high-quality welds

Thermacor Process main mission is to deliver consistent high-quality products. That’s why they’ve used the Rotoweld in their facilities since 1997. Thermacor Process was so impressed with their first purchase, they purchased a second Rotoweld in 2001–its new submerged arc welding feature is essential for their market–then added a third in 2017. Today, the two latest machines are still operating 40 to 60 hours a week.

The Number One reason they like the Rotoweld is for the consistent high-quality it delivers, resulting in a very low rework rate. The bottom line: they can deliver jobs on time at the lowest cost possible.

85%

40 to 60 hours

very low

Thermacor Process can deliver jobs faster than competitors

Thermacor Process has oriented their engineering and production planning so they can weld up to 85% of their spools with the Rotoweld and deliver jobs in less time than their competitors.

Ask for a demo today

We have over 150 Rotowelds at work around the world today. If you want to see a Rotoweld 3.0 in action, we can certainly make it happen.