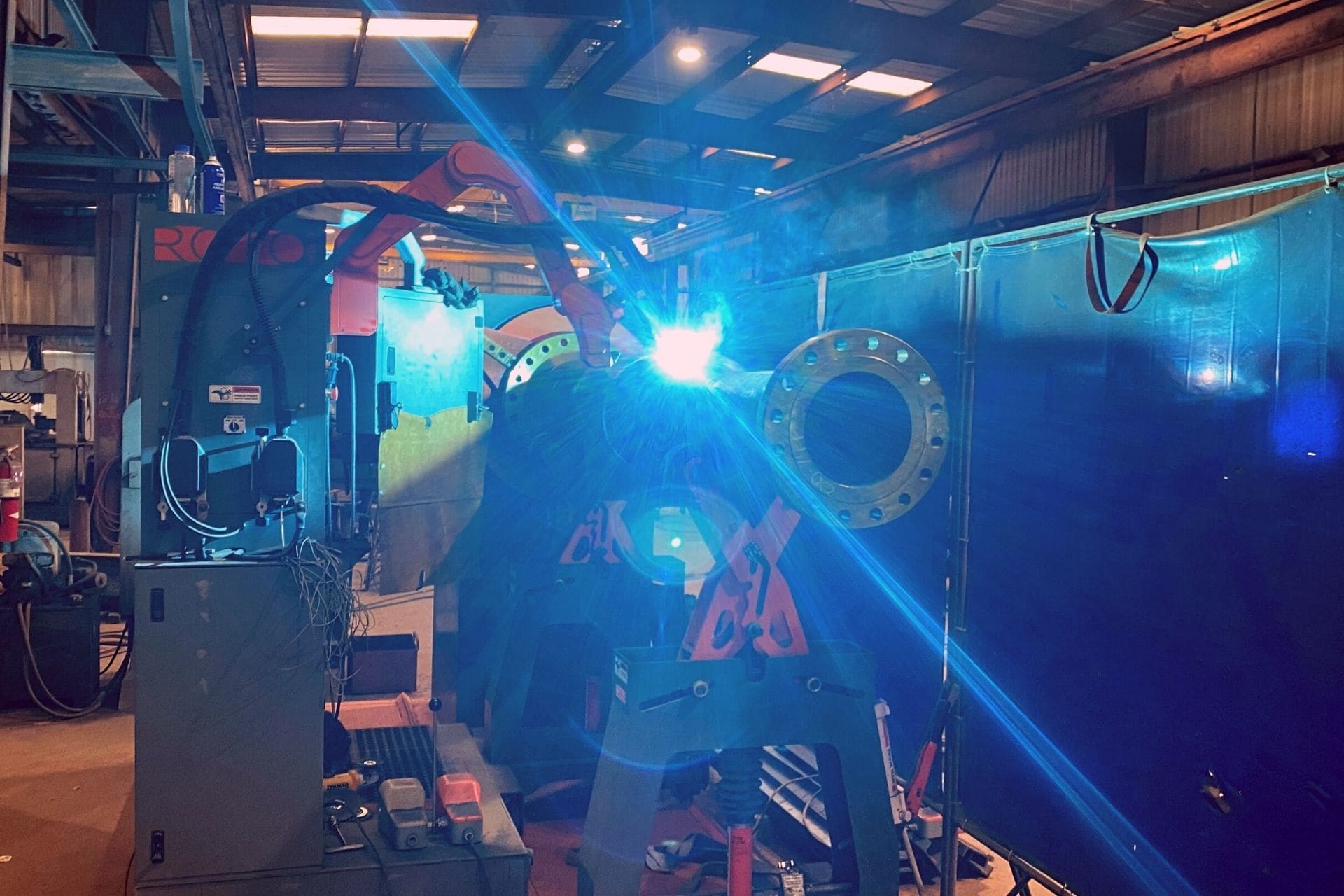

This mechanical contractor has been using the Rotoweld since 2003

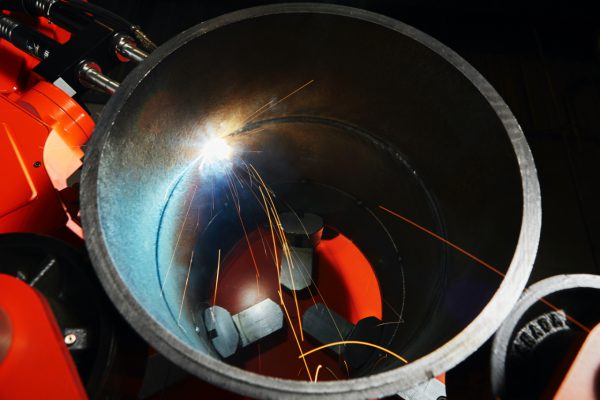

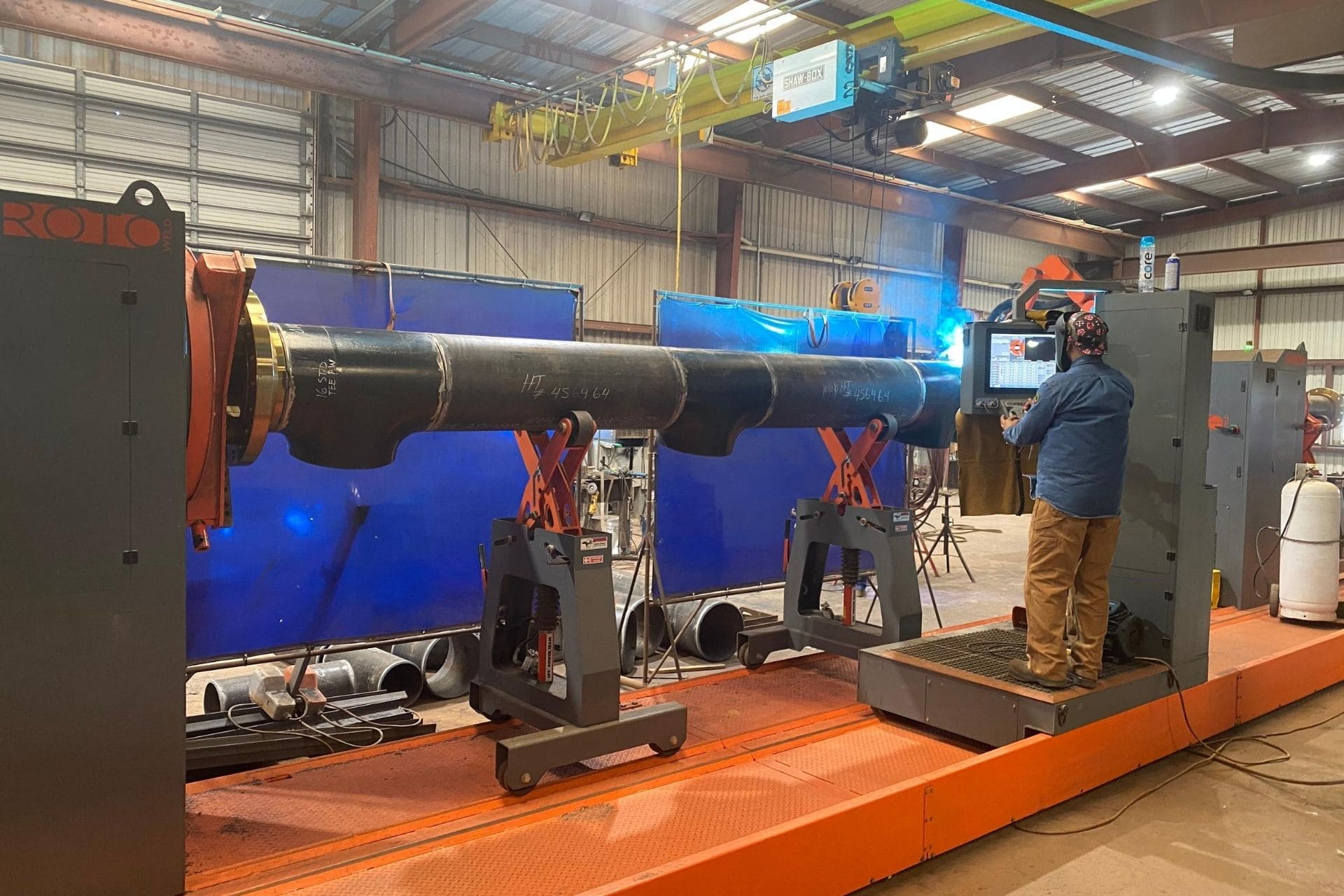

PWC Industries steel fabrication designers, welders and fabricators specialize in manufacturing high-quality metering and proving systems, ASME pressure vessels, holding and transport tanks, process and power piping and much more.

Key to addressing the shortage in the welding workforce

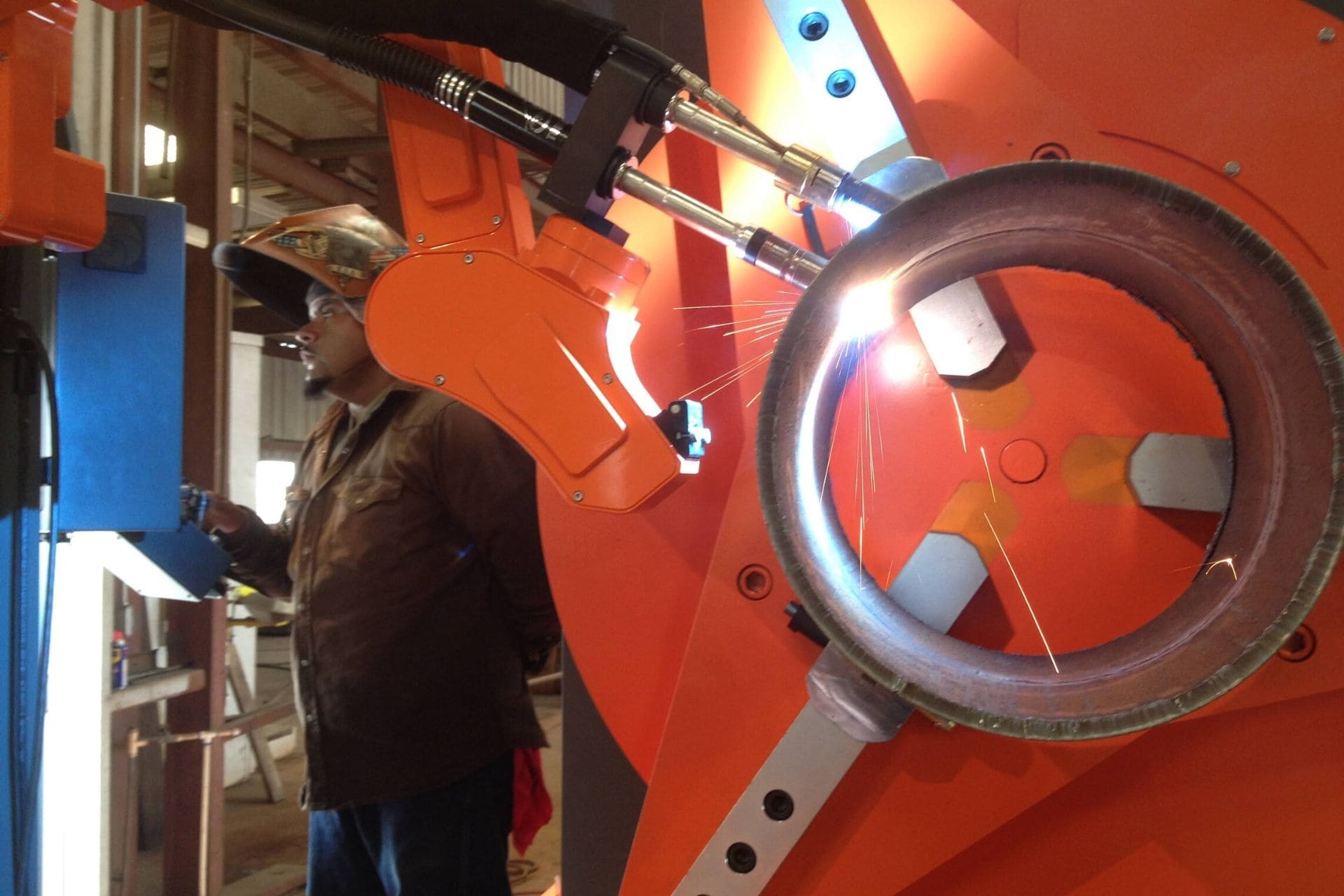

PWC industries was a typical small family-owned business that jumped into welding automation in 2003 and, since then, they renewed their Rotoweld for the 3.0 Twin Bay in 2015. The main goal was to run with minimum employees for maximum throughput, without affecting the quality and consistency. This strategy has never been more appropriate since, according to the American Welding Society, the industry will face a shortage of about 400,000 welding operators by 2024.

PWC’s investment in technology gives them the competitive advantage of building steel systems in less time than many other steel manufacturing businesses. This increased productivity is passed on to our customers in the form of decreased costs.

4x more productivity

twin bay

10 hours

Commitment to welding automation

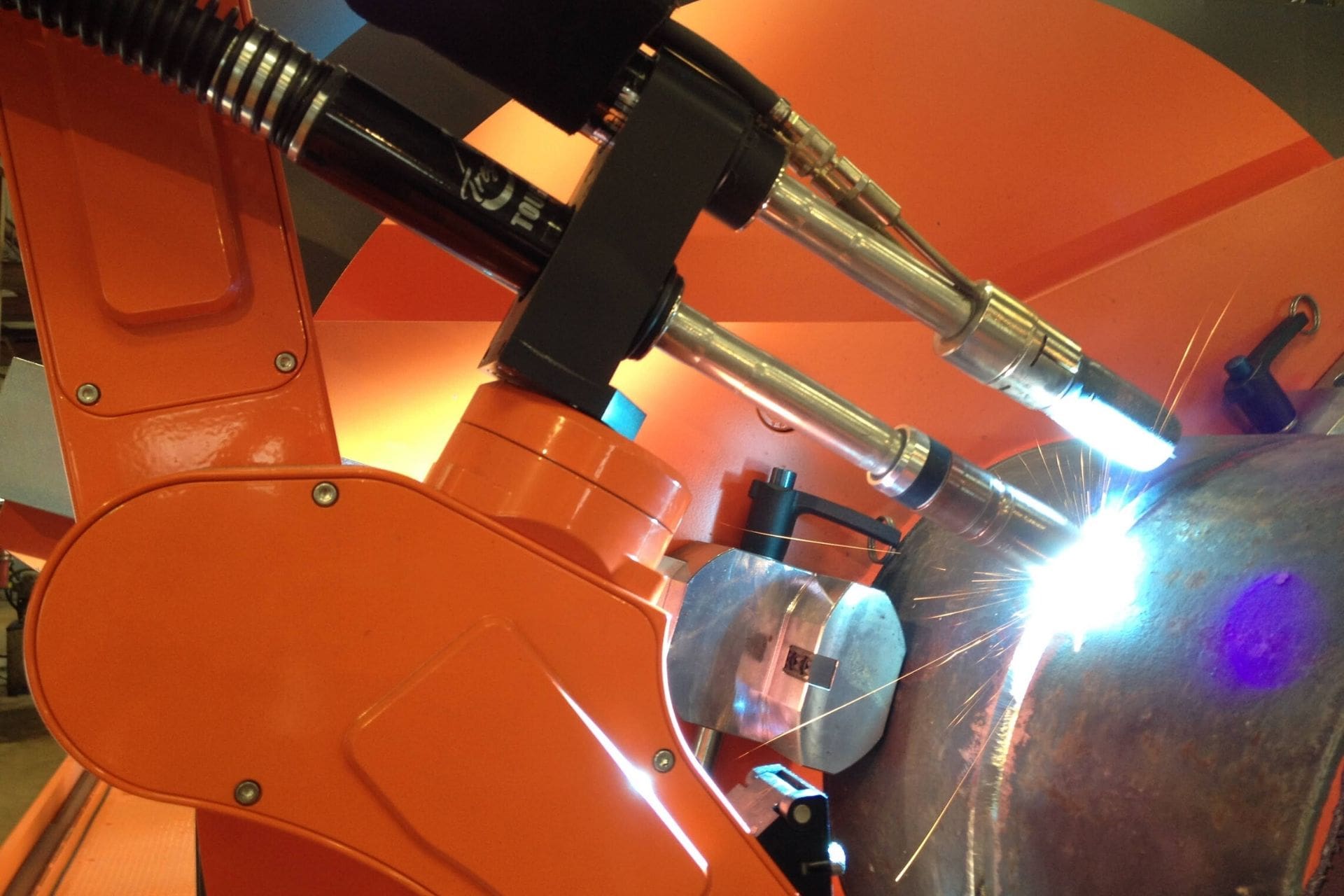

PWC is using the Rotoweld 3.0 Twin Bay to maximize their productivity. In a 10-hour shift they typically weld an average of 25 joints between 6- and 12-inch standard wall spools. The key to productivity is to be able to feed the machine and plan accordingly.

Ask for a demo today

We have over 150 Rotowelds at work around the world today. If you want to see a Rotoweld 3.0 in action we can certainly make it happen.