Rotoweld options

The Rotoweld has been around for over 30 years and we have been improving the machine to respond to the needs of the industry. Many options are available for a new or an existing Rotoweld.

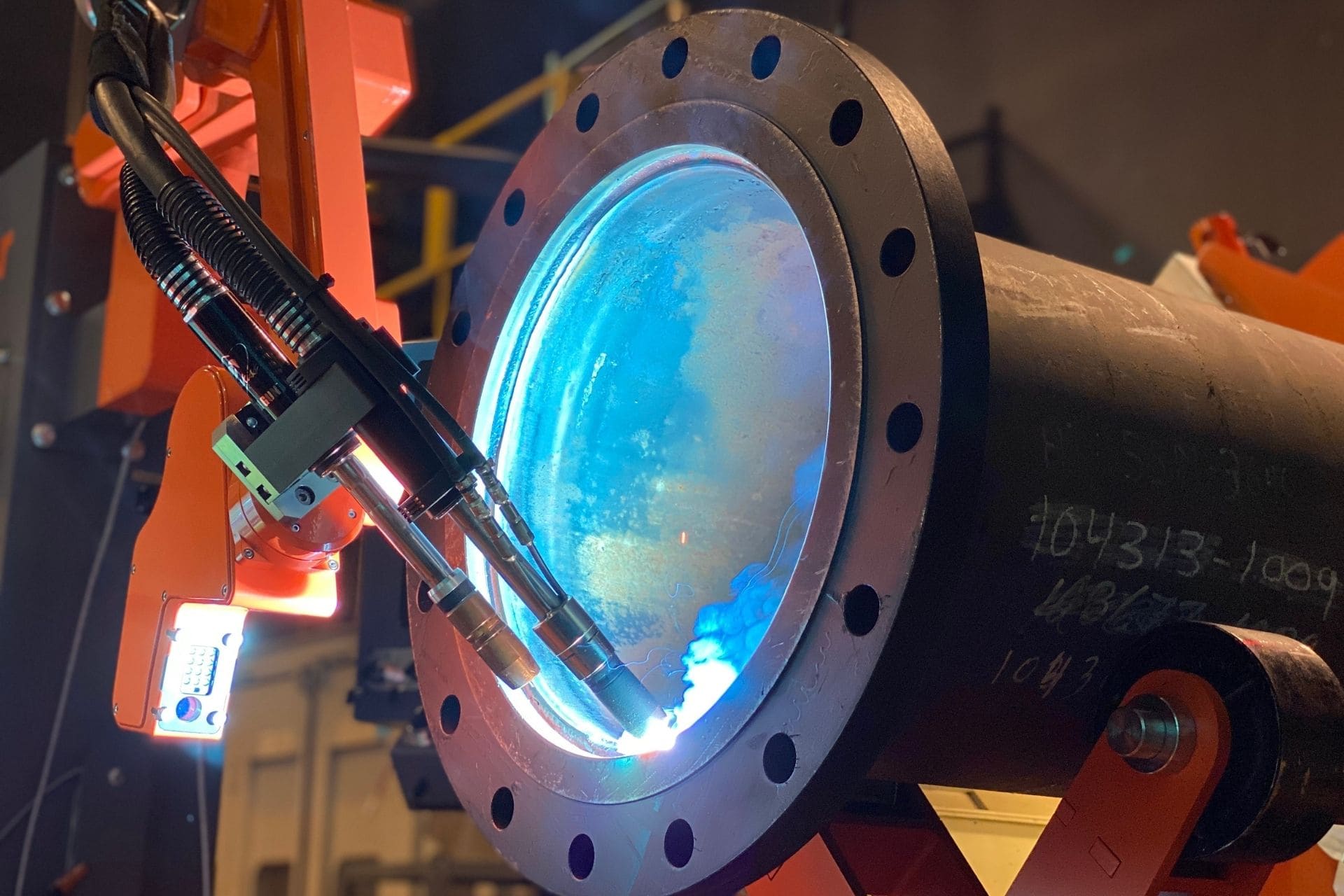

Talk to an expertSlip-on fillet welding

To optimize the number of joints that can be automatically welded in a fabrication shop, Tecnar has designed a Rotoweld 3.0 option to perform fillet welds on slip-on flanges.

Seamless integration

This option is a seamless enhancement of the Rotoweld’s manipulator in order to rotate the welding torches sideways, anywhere from 0 to 58 degrees, for both exterior and interior fillet welds.

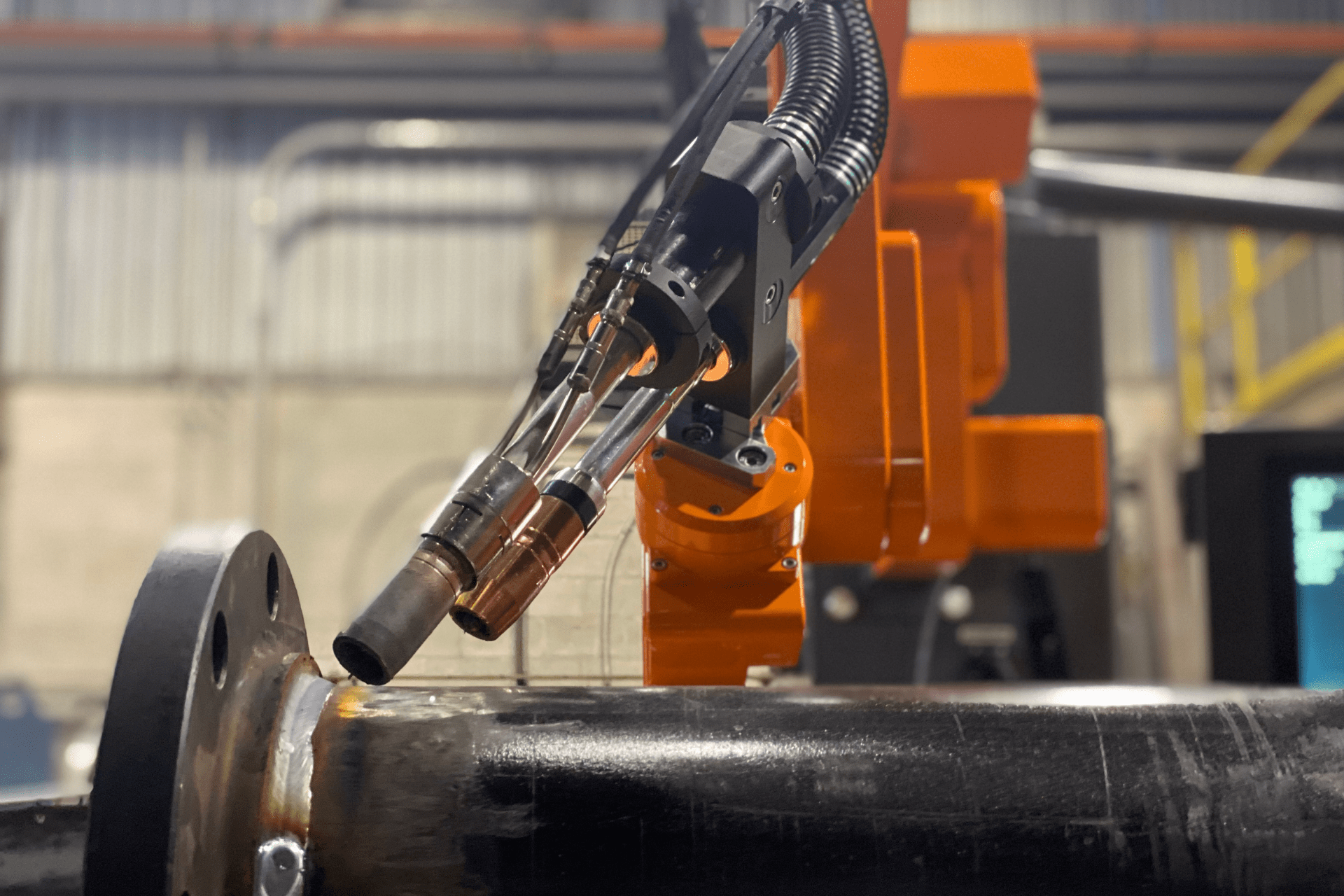

100% reproducibility

The torch angle and welding angle are adjustable on the welding program for absolute reproducibility and ease of use.

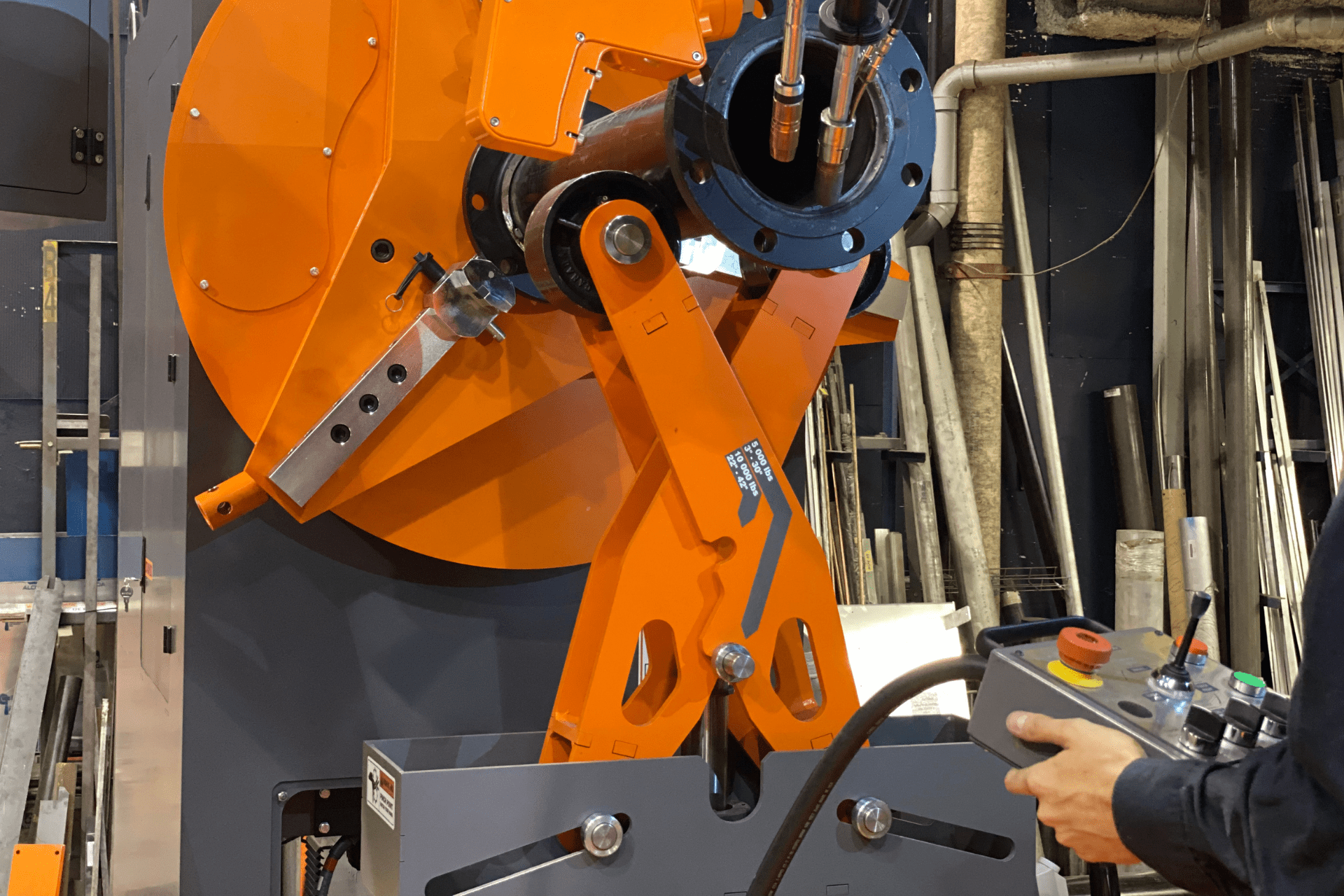

Fully automated positioning

The fillet weld option comes with a secondary remote control unit that can be displaced anywhere around the spool so operators can always keep an eye on the process.

SAW (submerged arc)

Get the advantage of achieving your root pass and SAW filling on the same machine while reducing the handling time, simplifying the shop operations and improving productivity.

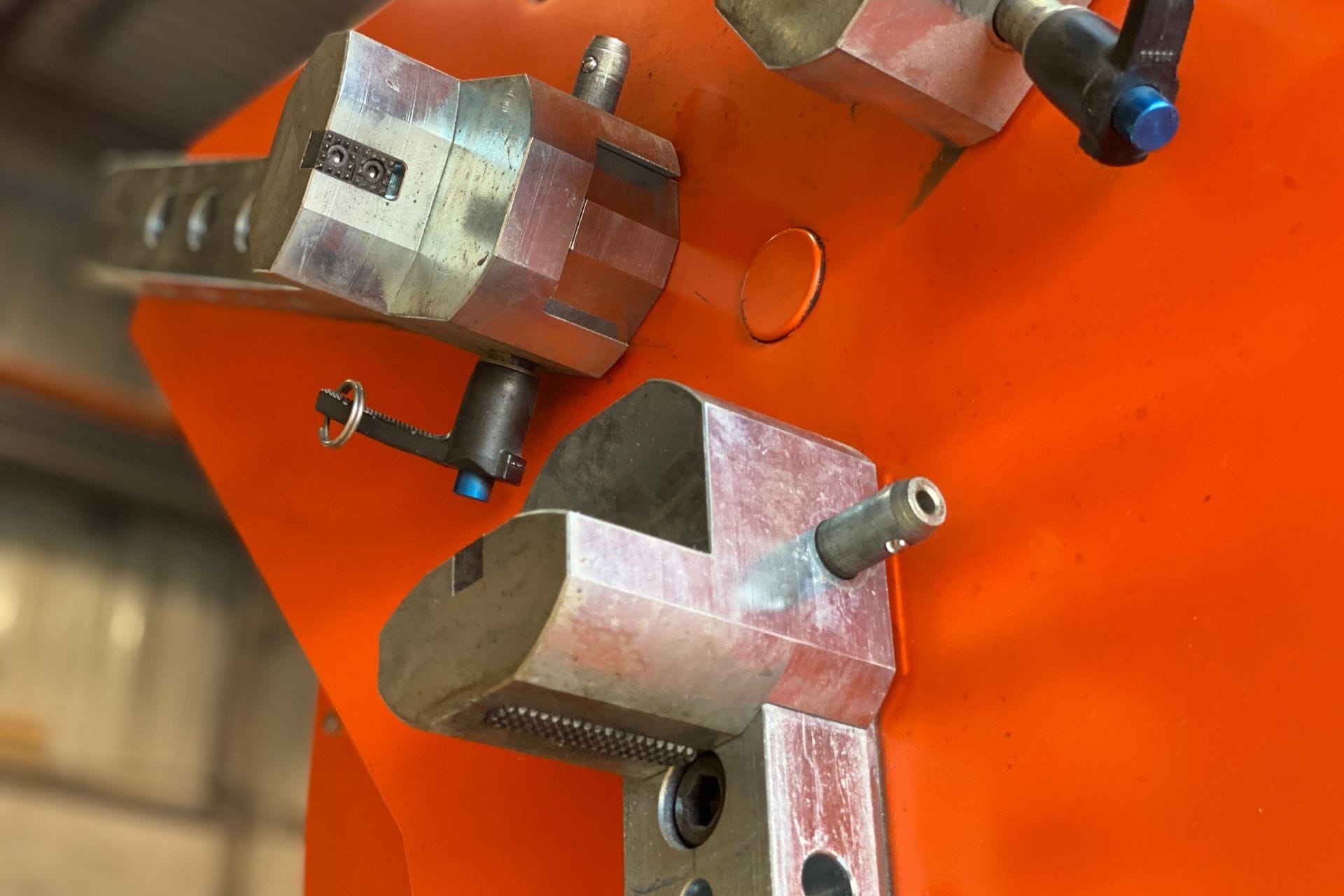

Dedicated twin torch holder

The SAW option features a dedicated twin torch holder with the MIG root pass torch and SAW torch kit for 3/32 wire. That means it takes less than 20 minutes to change the Rotoweld from the MIG-MIG to the MIG-SAW configuration.

Recovery bins

The proprietary designed flux recovery bins, engineered to be easily emptied, are a great advantage of the SAW option. They are mounted directly on the idler rolls so they can be easily placed under the joints and can be swapped from one side of the idler roll to the other in just 5 minutes.

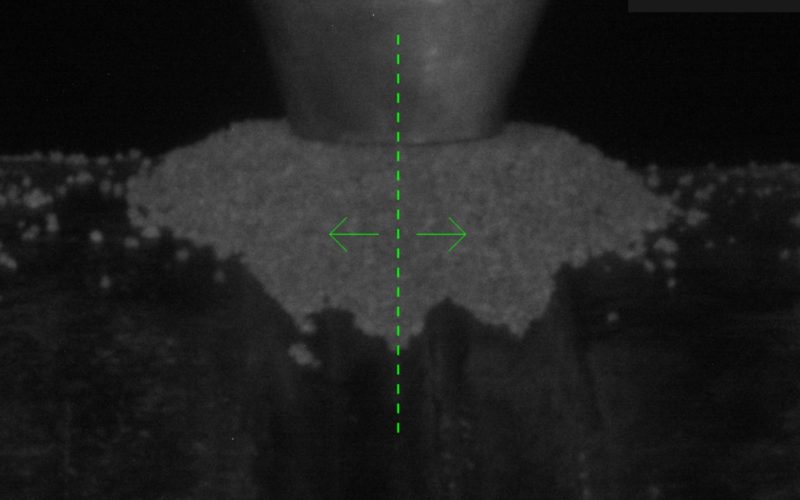

Adapted vision system

The Rotoweld’s LED vision system allows the SAW torch to be positioned on top of the pipe while safely staying on the welding carriage. The SAW vision mode also provides a linear guide as an overlay on the screen to help the welder create a smooth surface finish between passes.

Power source

Workflow tracking software

Compatible with workflow tracking software

The Rotoweld is compatible with MSUITE, STRATUS and PypeServer, making it a versatile tool for manufacturers who want to streamline their operations and work more efficiently.

- Easily identifies and pushes the weld ID and information to the Rotoweld software

- Automatically loads the right welding program, if specified

- Links the Prodatalog weld information to the shop’s valid weld ID

- Notifies the plant tracking software when the weld is complete

- Sends critical weld information to the weld ID, such as heat input and arc-on-time.

Fume extractor

The main feature of the fume extractor is that it is a fully integrated fume extraction system.

Welding fumes can be a threat to the welder’s health and it can make the shop environment an uncomfortable work space. And with the labour crisis in most developed economies, providing a safe work environment has become mandatory.

Self-positioning hood with welding carriage

Recovers the floor space required to move around mobile units

Easy-to-access pump and filters

Silent operation at the welding station

Easy to install and more affordable then wall-mounted systems

More environmentally friendly than wall-mounted systems

Technical specifications - Fume extractor

Vacuum

Max airflow

2 200 m³/hr

1 300 CFM

Max vaccum

6 000 Pa

24 in. WC

Performance

3 HP fan

3 HP fan

Noise level

67 dB @ 3m

67 dB @ 10 ft.

Filtration

Main filter surface

48 m²

520 sq. ft.

Filter efficiency

99.97% @ 3µm - HEPA

99.97% @ 3µm - HEPA

3 filter stages

Prefilter: spark trap

Main filter: MERV 15

After filter: HEPA

Prefilter: spark trap

Main filter: MERV 15

After filter: HEPA

Cleaning system

Self-control cleaning filter

Self-control cleaning filter

More options that can make the difference

FCAW (flux core)

Your Rotoweld 3.0 can easily be switched to FCAW since all you need are adapted feeder rolls. Get them on your initial order and be ready in no time, when needed, at minimal cost.

Stainless steel grippers

If you dedicate a Rotoweld for stainless steel operations, then it’s best to go for the highest standard and have all the grippers changed to stainless steel too.

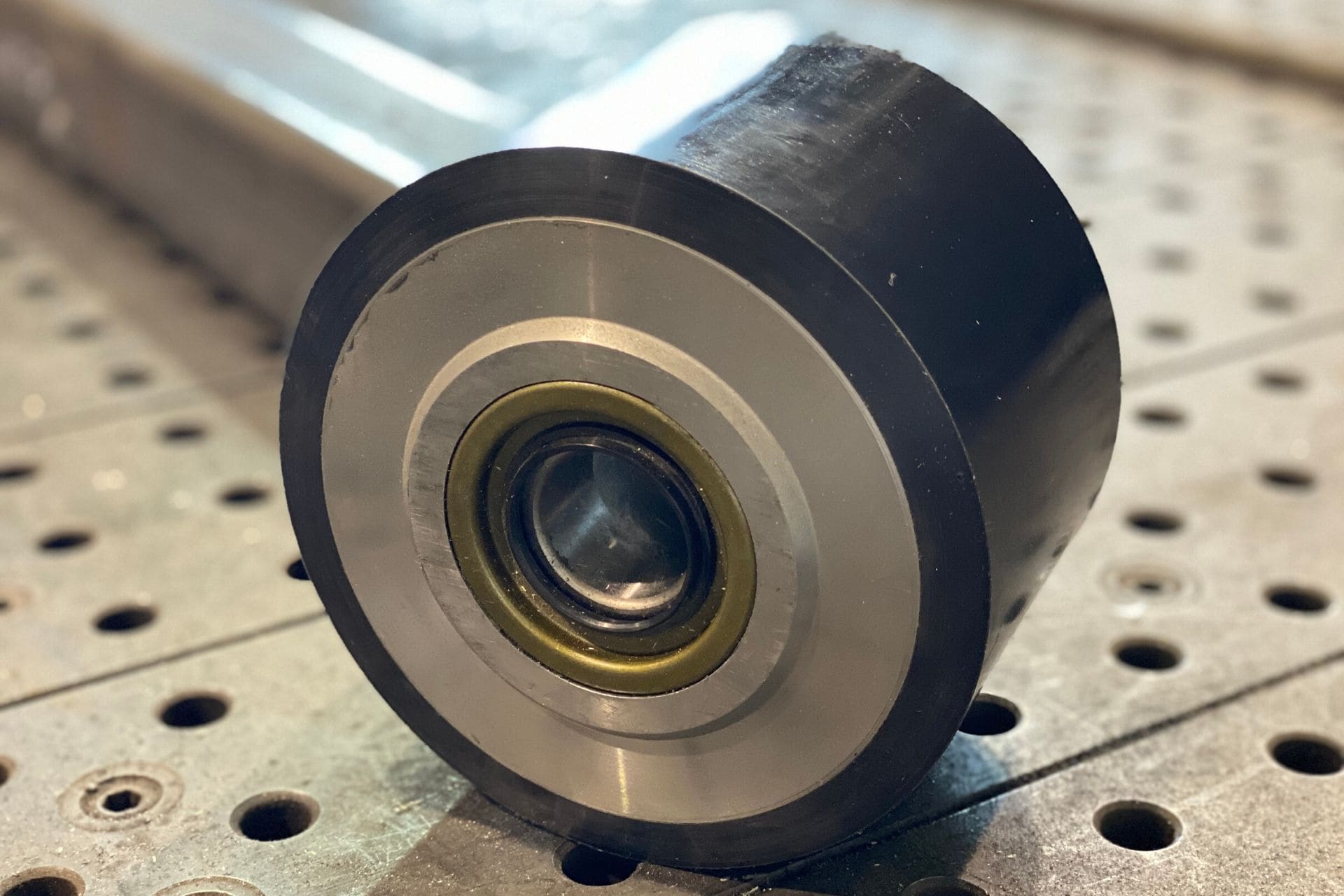

Rubber idler roll

If you dedicate a Rotoweld for stainless steel operations and want to avoid any contamination, the Rotoweld idler rolls can be ordered with high-capacity rubber sleeves that can sustain 15,000 lbs. / 6,804 kg of load while keeping your spools clean and smooth.

Interested in getting into pipe spool welding automation?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.