The only fully integrated design for 1G robotic pipe welding

The Rotoweld 3.0 is designed for the daily reality of pipe spool fabricators. We believe that only a fully integrated work cell can deliver our production promise to our clients: the most high-quality, reproducible, productive and consistent welds.

Talk to an expertFully integrated design advantage

The Rotoweld 3.0 is a turnkey monolithic product in which every component has been engineered to ensure the highest standards of productivity, quality and reliability.

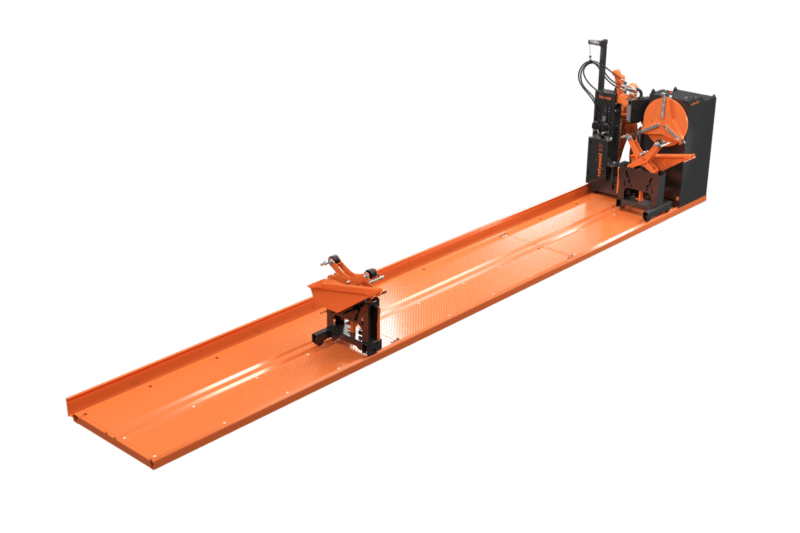

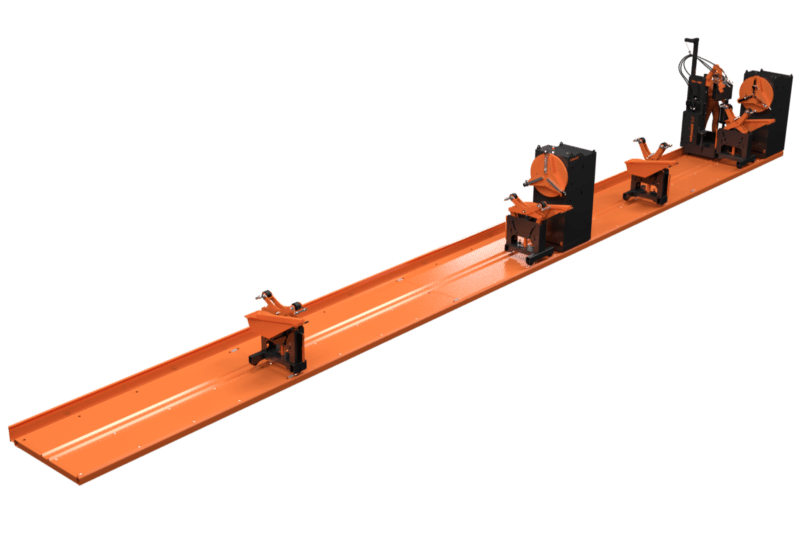

The rail-based system is the back bone of automated welding

The rail-based design is key to automation since it is the link between the welding robot, the rotators and the support rollers. That’s why it’s essential to ensure reproducible positioning of the welding torch (stick-out) and the same welding position every time, regardless of the diameter of the pipe or length of the spool assembly.

The welding robot is seamlessly carried to a second welding station along the rails, so the Twin Bay model eliminates set- up time and increases productivity.

What’s more, all the welding cables are embedded in the rail design for safer and simpler shop operations.

Robotic welding arm

Upon loading the proper welding program, the Rotoweld’s welding arm, driven by zero-backlash harmonic drives, will position itself automatically, respecting the pipe diameter and indicated stick-out.

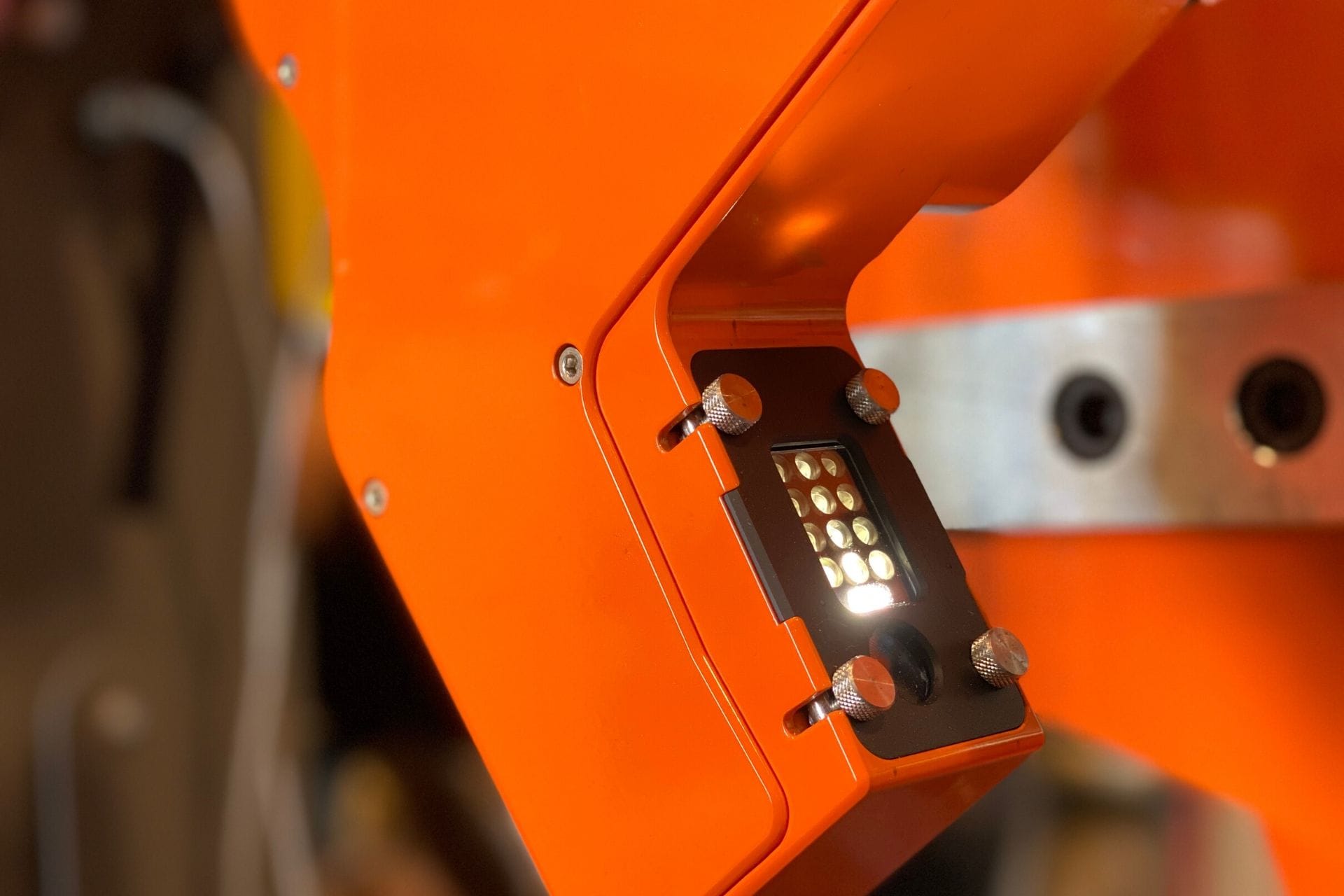

LED vision system

With the Rotoweld 3.0 LED vision system, the operator can keep comfortable in front of the monitor and easily align the torch in the bevel before starting to weld. For multi-pass filling, it provides greater precision than the eye, helping the operator achieve smoother surface finishes.

This off-arc vision system reproduces the comfort of liquid crystal welding masks, which welders used in the past 10 years. It’s also a great innovation for large diameters where the welding area is visually less accessible.

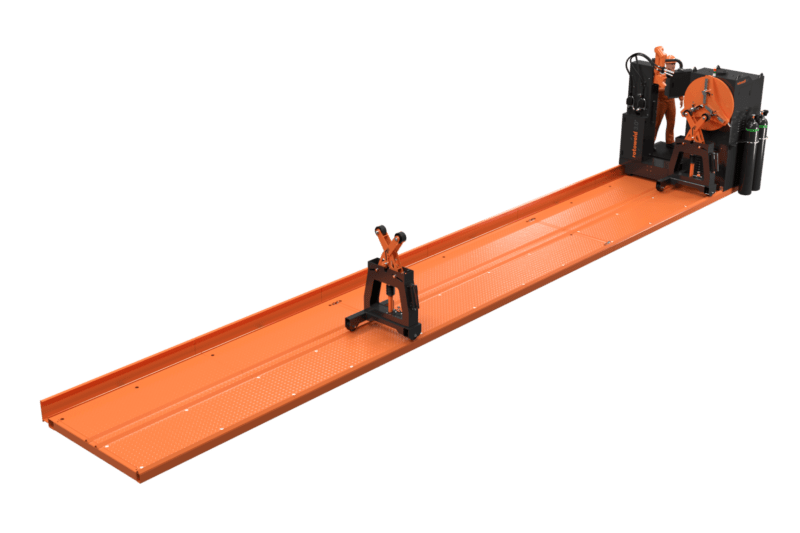

Pipe stands

Rotoweld 3.0 pipe stands are made to be simple, robust and versatile. They can handle up to 15,000 lbs. of weight and can be delivered with metal or rubber rollers.

They are essential for consistently welding spools in 1G and can easily travel along the rails while staying aligned with the rotator for better joint stability while welding.

Balanced high-range rotator

The rotators handle up to 3- to 48-inch diameter pipes and deliver 50,000 lbs./inch of torque. They are designed to be tough, easy to use and most importantly: perfectly aligned with the welding robot and rails. Their acceleration and velocity are calibrated with the 4D Synergy Welding™ software for optimal performance.

Optimized floor space

We know floor space and work flow are important. The Rotoweld’s integrated rails-based design boasts the highest floor space optimization on the market. It also leaves more room for adding pipe-fitting stations, which are key to feeding the Rotoweld at capacity. There is no better optimized solution than the Rotoweld for shop floor usage at equivalent productivity.

User Interface (UI)

The Rotoweld user interface is designed with proprietary operating software to be simple, easy to use and efficient. The Rotoweld UI features are:

- Large centred image to ease torch positioning using the LED vision system and increase welding precision

- Welding program architecture to facilitate the tracking of critical welding settings and the uploading of new welding programs

- Live display of all welding parameters, including welding current and live heat input

- A simple log-in function so Rotoweld operators can easily enter the ID and job number of work in progress.

Rotoweld 3.0 models

Ask for a demo today

We have 250 Rotowelds at work around the world today. If you want to see a Rotoweld 3.0 in action, we can certainly make it happen.