Phillips 66 Company

With more than 140 years of experience, they are a diversified energy manufacturing and logistics company with unique businesses in refining, midstream, chemicals and much more.

Quick response to facility failure

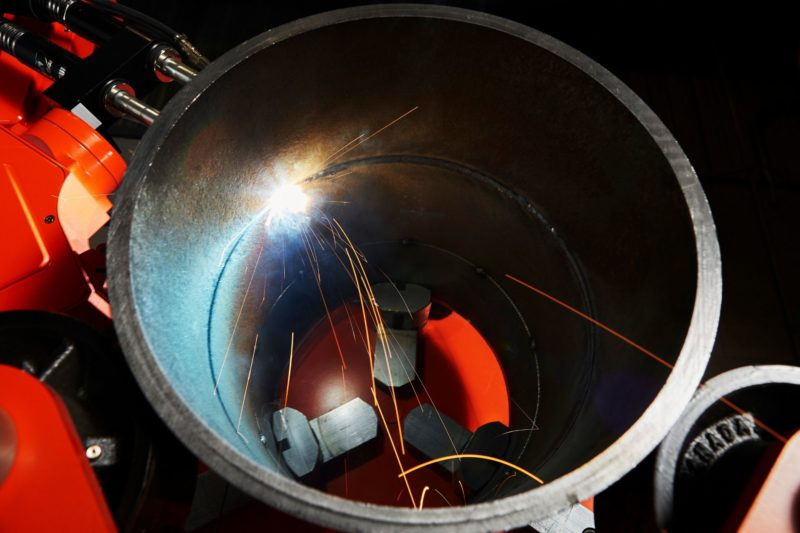

The first call for spool welding automation at Phillips 66 came from the maintenance and repair shop at the Ponca City refinery in Oklahoma. Supporting a large refinery can be very unpredictable. These shops need to deal with planned maintenance yet retain the capacity to react quickly to a pipe failure to minimize operational downtimes.

For Henry Johnston, head of the repair facility, the Rotoweld 3.0 Single Bay, means he can maximize productivity on a rush repair while keeping a small, effective team of welders on duty.

less labour

for the same throughput

high-quality

weld every single time

turn around

less downtime for the plant

Consistent high quality becomes the standard

Besides resolving a labour challenge, the Rotoweld 3.0 Single Bay, the product line’s most affordable package, has given Phillips 66 a new level of consistent high-quality welds by continuing to deliver 100% of the automated welding stations’ core technology and integrated design.

Ask for a demo today

We have over 150 Rotowelds at work around the world today. If you want to see a Rotoweld 3.0 in action, we can certainly make it happen.